In today’s construction industry, pvc window profile extrusion in India is becoming a preferred choice for bulk buyers and manufacturers. These profiles are designed to last longer and perform better in changing climates, which helps reduce costly repairs and frequent replacements. For builders, contractors, and suppliers, choosing PVC profiles means fewer long-term issues and more reliable results.

Why Repair and Replacement Costs Are a Concern

Window systems are critical for insulation, safety, and overall building performance. When frames are made from materials that cannot handle heat, moisture, or heavy use, problems such as leakage, cracks, and warping often appear. These issues lead to frequent replacements that raise budgets and delay project timelines. For companies managing large developments, this creates unnecessary expenses and customer dissatisfaction.

The Role of PVC in Modern Window Profiles

PVC, or polyvinyl chloride, has emerged as a leading choice in window profile production. It offers a range of advantages that help prevent long-term maintenance problems:

- Weather resistance as it performs well in hot summers, heavy rains, and humid conditions

- Durability as it resists corrosion and impact, extending the service life of windows

- Low maintenance since it does not need regular painting or polishing

- Energy efficiency by improving insulation and lowering heating and cooling needs

By using PVC profiles, businesses can ensure that windows stay functional without requiring constant attention.

The Extrusion Process and Its Impact on Quality

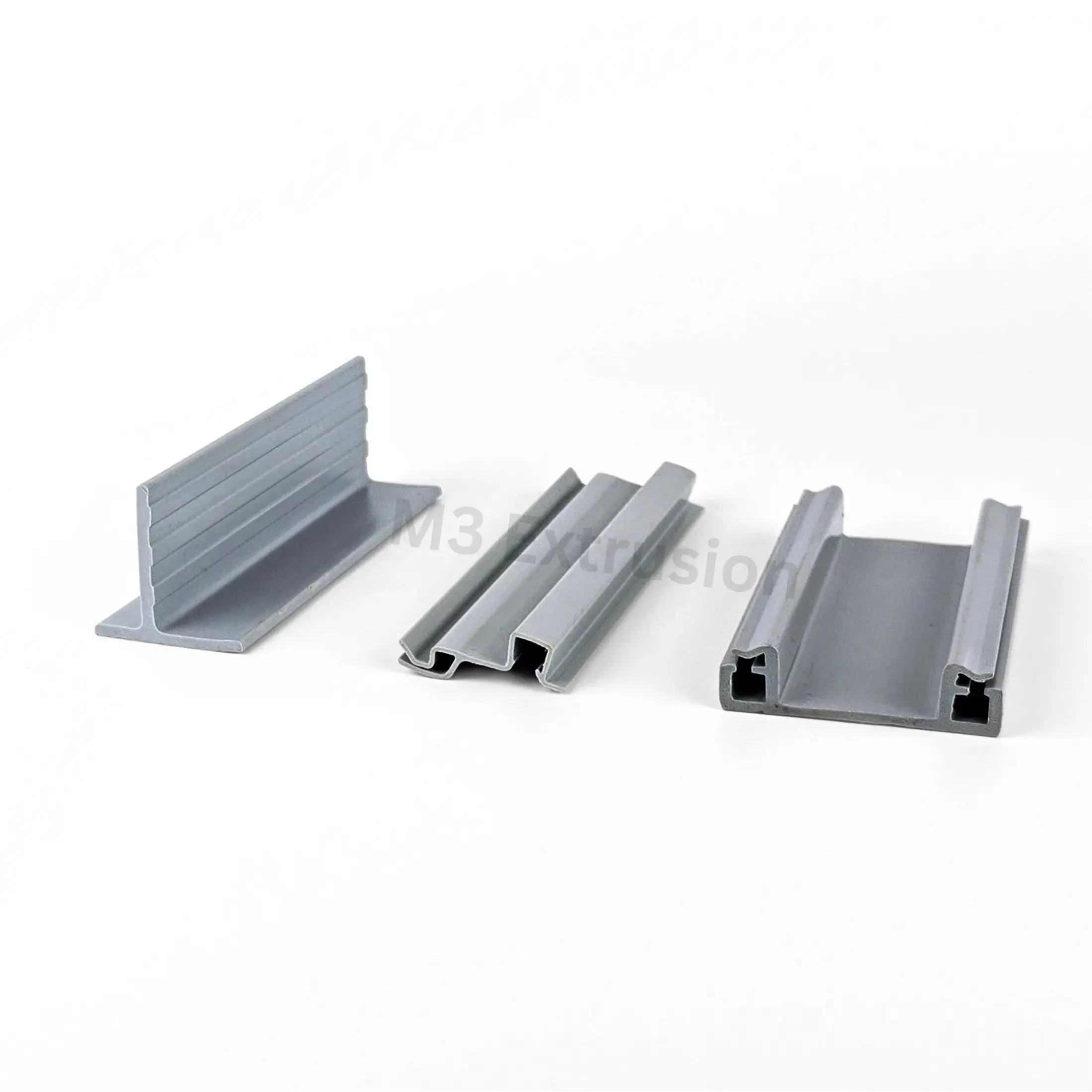

PVC window profiles are made using an extrusion process where heated PVC is shaped through precision dies. This method ensures:

- Consistent dimensions and uniform quality

- Smooth finishes that make installation easier

- Flexibility to produce customised shapes for unique projects

For bulk buyers, extrusion provides assurance that every order meets the same quality standards, which reduces the chances of product failure during or after installation.

Cost Benefits for Bulk Buyers

While some materials appear cheaper in the short term, they often fail to provide value in the long run. PVC profiles reduce these risks by offering:

- Longer life cycles which cut down on replacements

- Fewer disruptions to projects due to faulty materials

- Predictable performance across bulk supply orders

This translates into stronger returns on investment and improved customer satisfaction for construction companies and traders.

Supporting Large-Scale Projects

Builders and contractors often face strict deadlines and limited budgets. Window systems play a crucial role because any failure affects comfort, safety, and overall building quality. By selecting PVC profiles, developers can reduce the number of service calls and warranty claims. This makes them especially suitable for housing projects, office buildings, and institutional facilities where long-term stability is important.

One important part of this reliability is choosing the right materials for long-lasting window frame seals, since poor sealing often leads to leaks, noise, and higher maintenance costs. Pairing durable seals with PVC profiles strengthens the overall system and keeps projects efficient over time.

How PVC Profile Extrusion Supports Long-Term Efficiency

In large developments, efficiency is just as important as quality. PVC extrusion makes it possible to produce profiles that are lightweight, strong, and simple to install. This provides:

- Faster installation that reduces labour costs

- Consistency that lowers the chance of delays caused by defects

- Long-term durability that limits after-sales service issues

Together, these factors improve project outcomes and reduce the hidden costs of maintenance. Many construction firms now view custom extruded plastic in India as a practical way to secure reliable materials that fit long-term planning.

Applications of PVC Profiles

PVC profiles are widely used in window systems but their applications extend further. They are also suitable for:

- Sliding and casement windows

- Doors and partitions

- Skylights and conservatories

For businesses working across different sectors, the versatility of PVC profiles makes them a practical choice for multiple applications. Many suppliers now focus on plastic extrusion for construction and fenestration, ensuring consistency across different building solutions.

Why Indian Businesses Prefer PVC Profiles

India’s climate varies from region to region, with extreme summers in some cities and heavy monsoons in others. PVC profiles perform well under these conditions, making them a reliable option for builders and manufacturers. Companies like M3 Extrusion provide bulk supply of these profiles, helping industries secure durable solutions at scale. Their focus on quality extrusion ensures consistent results for every order.

FAQs

- What makes PVC window profiles better than wood or metal?

PVC profiles do not warp, rust, or decay. They last longer, require little maintenance, and provide better insulation. - Are PVC profiles suitable for large-scale construction?

Yes. They are lightweight, durable, and available in bulk, which makes them practical for large housing projects, commercial spaces, and institutional buildings. - How does extrusion improve PVC profile performance?

The extrusion process creates uniform shapes and strong finishes, ensuring profiles are reliable, easy to install, and long lasting. - Can PVC profiles lower long-term costs?

Yes. By reducing repair and replacement needs, PVC profiles help cut maintenance expenses and extend the value of investments. - Where else can PVC profiles be used besides windows?

They can also be used in doors, skylights, and partitions, making them suitable for different construction needs. Many companies also use uPVC window seals to support airtight and energy-efficient designs.

Conclusion

PVC window profiles provide a strong solution for reducing repair and replacement problems in both residential and commercial projects. Their durability, weather resistance, and energy-saving qualities ensure they perform reliably in different environments. The extrusion process adds further value by maintaining consistency and quality across every batch. For bulk buyers and manufacturers, these benefits support long-term efficiency and cost savings in projects.