Over the years, co-extrusion has become a practical and effective way to improve PVC profiles. Made by combining two or more layers of PVC in a single process, it gives each layer a specific role. One layer adds strength, while another improves the surface or protects against weather and daily wear.

Not only does this make profiles stronger and more durable, but it also helps them resist heat, moisture, and other common stresses.

This process allows manufacturers to create high-quality profiles without adding extra weight or cost. Today, PVC co-extrusion in India is widely used in windows, doors, pipes, and panels, helping them last longer and perform better in real-life use.

What is co-extrusion of PVC profiles?

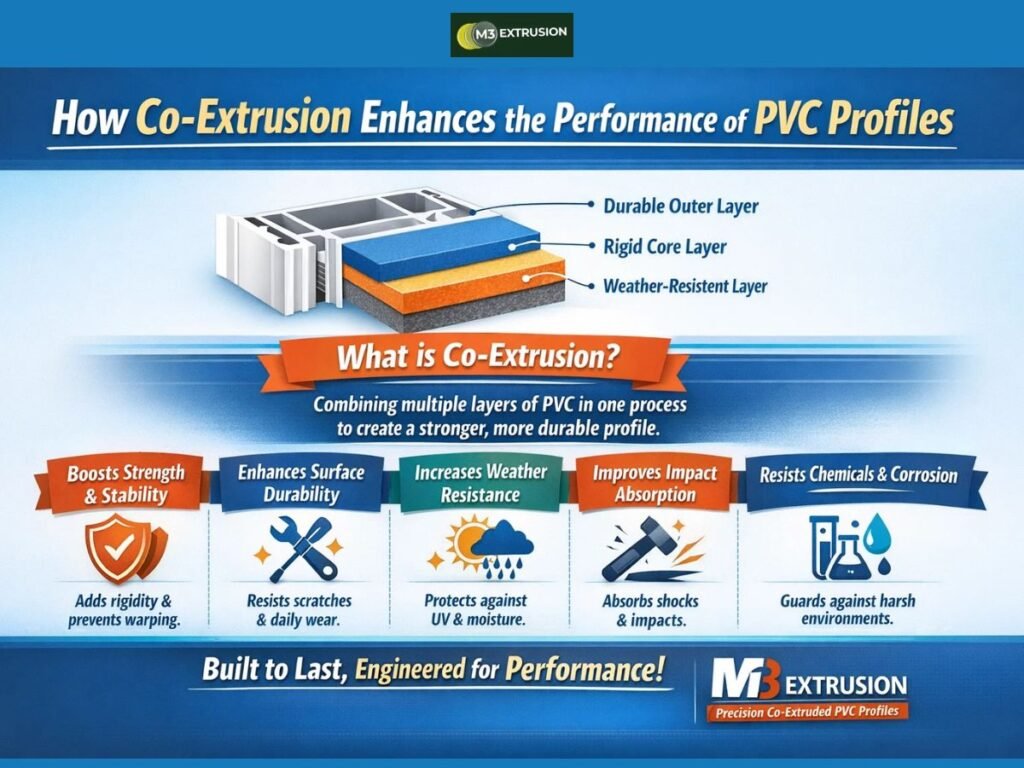

As the name suggests, co-extrusion of PVC profiles is the process of forming two or more layers of PVC together in a single run. Each layer has a specific role. One layer adds strength and stability, another improves the surface finish, and some layers protect against weather, moisture, or everyday wear.

The layers bond while still hot, creating a single, durable profile once cooled. This method makes PVC profiles stronger, longer-lasting, and more resistant to stress than single-layer products.

PVC co-extrusion technology is widely used in windows, doors, pipes and panels because it combines performance, durability, and appearance in one product. It also allows manufacturers to meet high standards without adding extra weight or cost.

5 Ways Co-Extrusion Enhances PVC Profile Performance

With co-extrusion, PVC profiles gain layers that improve strength, protection, and performance. Each layer has a role to play. Some add rigidity, making the profile sturdy and less likely to bend or warp. Others focus on the surface, giving it a smooth finish that resists scratches, dirt and discoloration.

Certain layers act as shields against heat, moisture or daily wear, helping the profile last longer even in tough conditions. This layered structure also reduces weak points, which makes production more consistent and reliable.

Profiles made this way are easier to maintain and retain their shape and look over time. Bringing all these layers together in one process gives PVC profiles the strength and durability needed for everyday use in windows, doors, pipes, and panels. The profiles stay reliable over time while keeping weight and cost low.

Here are five ways co-extrusion enhances PVC profile performance.

Improves Strength and Stability

Since co-extruded PVC profiles are made of multiple bonded PVC layers, they provide structural rigidity and support, helping windows, doors and panels remain strong and reliable even under frequent use.

- Handles daily stress: The core and outer PVC layers distribute mechanical loads and minor impacts, ensuring the profile maintains its shape and strength during regular operation.

- Protects fittings and joints: Layered construction reduces stress around hinges, locks and fasteners, keeping these components secure and functional over time.

- Maintains frame stability: The synergy of PVC layers prevents bending, warping, or deformation, preserving the profile’s alignment and overall structural integrity.

By combining layers that resist impact and stress, co-extruded PVC profiles stay durable, stable and reliable for long-term performance.

Enhances Surface Durability and Scratch Resistance

In addition to improving the strength and stability of PVC profiles, co-extrusion also strengthens the surface, giving it better resistance to scratches, abrasions, and minor impacts. This helps windows, doors, and panels maintain a smooth, even finish over time.

- Resists everyday wear: Co-extrusion creates a tough outer layer that protects against scuffs, knocks and friction from daily use, keeping the profile looking new for longer.

- Prevents surface damage to fittings: The co-extruded surface layer reduces the risk of scratches near locks, handles, and hinges, protecting both the profile and attached components.

- Maintains aesthetic quality: Through co-extrusion, the scratch-resistant layer ensures the profile’s appearance stays uniform, smooth, and clean, even in high-traffic areas.

The co-extruded surface ensures the PVC profile resists scratches and wear, keeping it smooth, durable, and visually intact even after years of daily use.

Increases Weather and UV Resistance

With co-extrusion, PVC profiles gain protective layers that act as a barrier against sunlight, moisture, and temperature changes, helping them endure harsh outdoor conditions without losing strength or surface quality.

- Shields against UV damage: Co-extruded surface layers prevent discoloration, fading, and surface brittleness caused by prolonged exposure to sunlight.

- Protects against moisture: The layered construction reduces water absorption, preventing swelling, warping, or structural weakening in rainy or humid environments.

- Maintains outdoor performance: By combining UV-resistant and moisture-protective layers, co-extruded profiles retain strength, alignment and surface quality even under extreme weather conditions.

The co-extruded layers ensure PVC profiles remain durable, stable and visually consistent, making them reliable for long-term outdoor use.

Enhances Impact and Shock Absorption

Co-extrusion gives PVC profiles a layered structure that absorbs and spreads impact energy, helping them withstand knocks, bumps and everyday stress without losing shape or strength.

- Distributes force efficiently: Co-extrusion allows the core and outer PVC layers to work together, spreading mechanical energy evenly across the profile and preventing damage in specific areas.

- Protects fittings and joints: Co-extruded layers cushion hinges, locks, and fasteners against shocks, maintaining secure attachment and preventing loosening over time.

- Maintains structural integrity: Through co-extrusion, the layered construction absorbs impacts while preserving frame alignment and overall profile strength, even under repeated stress or heavy use.

The co-extruded design ensures PVC profiles remain robust, stable and capable of handling impacts, delivering long-lasting performance and reliability.

Improves Chemical and Corrosion Resistance

Because co-extrusion allows multiple PVC layers to be tailored for specific protection, profiles resist chemical exposure and corrosion, making them suitable for industrial, coastal and high-moisture environments. The layered design safeguards both surface and core structure.

- Shields against chemicals: Through co-extrusion, the outer PVC layers are engineered to resist damage from cleaning agents, solvents and other chemicals, which helps prevent surface erosion and preserve profile integrity.

- Prevents corrosion in humid conditions: The bonded PVC layers reduce moisture penetration, limiting rust or corrosion on fittings and ensuring structural stability over time.

- Maintains long-term performance: With co-extrusion, layered protection helps preserve the mechanical strength and appearance of PVC profiles, even under repeated chemical exposure or corrosive environments.

The co-extruded layers ensure PVC profiles remain durable, reliable, and resistant to chemical and corrosion damage for years of use.

Conclusion

Co-extrusion plays a key role in improving how PVC profiles perform in real-world conditions. By allowing different PVC layers to work together, the process strengthens structure, protects surfaces and improves resistance to impact, weather, chemicals and daily stress.

These technical improvements help profiles maintain shape, alignment and appearance over long periods of use. Co-extrusion also helps maintain consistent quality as well as dependable performance across many different applications. As the demand for PVC profiles rises, co-extrusion provides a practical way to meet these needs without adding extra material or complexity.

The result is a well-balanced profile that delivers durability, stability, and dependable performance where it matters most.

Are you looking for high-quality co-extruded PVC profiles for demanding applications? M3 Extrusion specializes in precision-engineered co-extruded PVC profiles designed to deliver strong wear resistance, reliable weather protection and long-term UV stability across a wide range of uses.

Frequently Asked Questions

Is co-extrusion an affordable method for making PVC profiles?

Co-extrusion strengthens PVC profiles and adds durability without increasing material or production costs, making it a practical and cost-effective way to produce high-quality profiles.

Why is co-extrusion preferred over single-layer PVC profiles?

Co-extrusion produces profiles that are stronger, more durable and more consistent than single-layer options. It also allows manufacturers to combine protection, appearance and performance in one product, meeting higher standards for real-world use.

How does co-extrusion impact product lifespan?

Co-extrusion extends the lifespan of PVC profiles by combining layers designed for durability, surface protection and environmental resistance, helping products withstand long-term wear, weather changes, and daily usage.

Do co-extruded profiles require special maintenance?

No special care is needed for co-extruded profiles. Their protective layers help prevent dirt buildup, scratches and fading, requiring only routine cleaning to stay in good shape.

Check related articles for more insights:

- How PVC Co-Extrusion Helps Manufacturers Achieve Stronger and More Durable Profiles

- 10 Applications of PVC Co-Extrusion in Commercial and Industrial Sectors

- PVC Co-Extrusion in India: Growing Demand Across Industrial Applications

- Why PVC Co-Extrusion Is the Answer to Long-Lasting and Reliable Seals