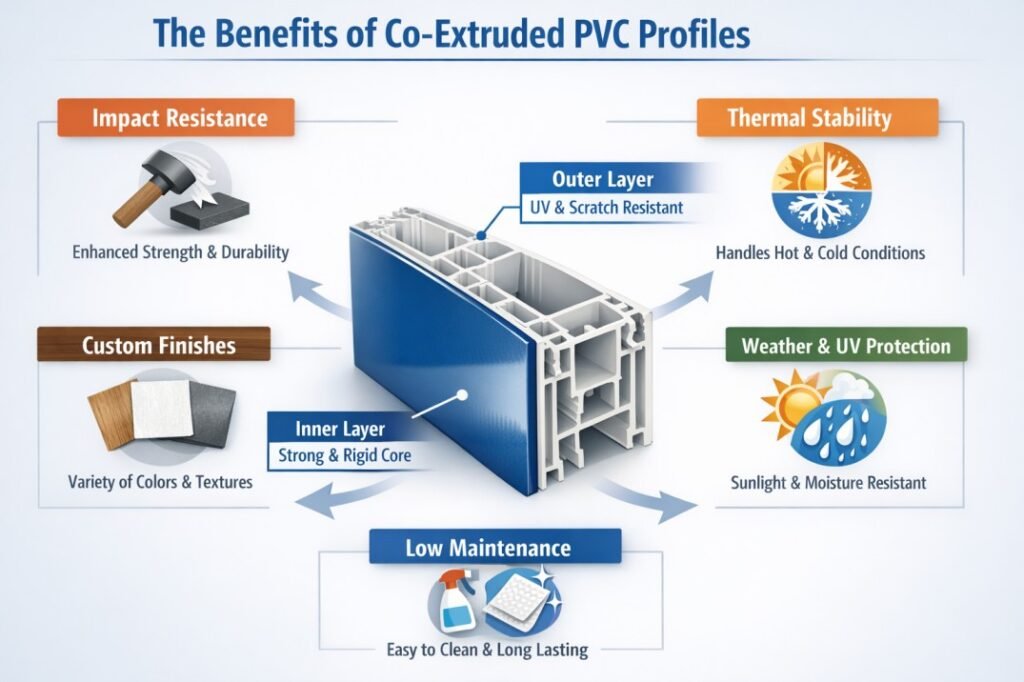

In today’s building and construction industry, co-extrusion has become a key method for making high-quality PVC profiles. It allows manufacturers to combine two layers in one profile, giving each layer a different purpose. Not only does this make the product stronger and more durable, but it also improves appearance and functionality.

The outer layer can resist scratches, stains, and sunlight, while the inner layer adds strength and reduces costs. This means PVC co-extrusion profiles look good, last longer, and perform well under daily use.

With co-extrusion, it is possible to create profiles in different colours, textures, and finishes without compromising strength. Maintenance is also easier, as the surface stays clean and resists damage from cleaning products or weather.

Key Benefits of Co-Extrusion for PVC Profiles

With co-extrusion, PVC profiles gain impact resistance, thermal stability, and consistent performance over time. The process combines multiple layers, each made from materials chosen for specific functions. The outer layer protects against scratches, stains, and UV damage, while the inner layer adds strength and rigidity.

Manufacturers can also include compounds in certain layers to enhance fire resistance, soundproofing, or chemical protection without affecting the rest of the profile. The PVC profile co-extrusion process supports complex designs, such as multi-chambered profiles, which increase energy efficiency and structural support.

By maintaining precise tolerances during production, these profiles fit accurately and require minimal adjustment during installation, making them reliable and durable for industrial and construction applications.

Listed below are five major benefits of co-extrusion for PVC profiles.

Increases Impact Resistance

One of the major benefits of co-extrusion is the fact that it enables PVC profiles to withstand daily mechanical stress. The co-extrusion process bonds multiple PVC layers, giving the profiles greater strength and stiffness, which helps windows, doors, and panels stay reliable under frequent use.

- Handles daily stress: Co-extrusion bonds multiple PVC layers into a single profile, which spreads mechanical forces across the layers. This prevents cracks or bending, allowing windows, doors and panels to withstand everyday use.

- Maintains frame stability: The layered structure created via co-extrusion ensures profiles retain alignment and shape, preserving overall structural integrity.

- Protects fittings and joints: co-extrusion strengthens areas around hinges, locks and fasteners, keeping components secure and preventing loosening or damage during operation.

By combining layers that resist impact and distribute stress, co-extrusion ensures PVC profiles stay strong, stable, and reliable over time.

Improves Thermal Stability

In addition to increasing impact resistance, co-extrusion also helps PVC profiles stay stable in extreme temperatures. By creating multiple layers with complementary properties, the profiles expand and contract less, reducing the risk of warping, bending or deformation.

- Handles temperature fluctuations: co-extrusion distributes thermal stress across the profile, keeping doors, windows and panels aligned and functional even in hot or cold conditions.

- Maintains structural integrity: The layered structure formed through co-extrusion ensures the profile retains its shape and strength despite repeated heating and cooling cycles.

- Supports long-term performance: Profiles produced via co-extrusion resist warping and bending, ensuring durability, reliability, and proper fit over years of temperature changes.

Overall, co-extrusion helps PVC profiles maintain shape, strength, and reliability over time, even under extreme temperature changes.

Enables Custom Finishes

With co-extrusion, you can create PVC profiles in a wide variety of colours, textures and surface finishes without compromising strength or durability. Co-extrusion lets the outer layer showcase any colour or texture, while the inner layers keep the profile strong and durable.

- Supports diverse textures and colours: co-extrusion allows wood-like, glossy or matte finishes, giving designers and builders flexibility in aesthetics.

- Maintains durability with custom surfaces: The outer layer formed through co-extrusion resists scratches, stains and UV damage, ensuring the profile’s appearance lasts over time.

- Combines style and function: co-extrusion ensures profiles meet both visual and performance requirements, delivering attractive yet robust solutions for windows, doors, and panels.

By combining a customisable outer layer with durable inner layers, co-extrusion produces PVC profiles that are both visually appealing and built to last.

Enhances Weather and UV Durability

Since co-extrusion adds protective layers to PVC profiles, they can withstand sunlight, moisture, and temperature changes, allowing them to endure harsh outdoor conditions without losing strength or surface quality.

- Shields against UV damage: Co-extruded surface layers prevent discolouration, fading, and brittleness caused by prolonged exposure to sunlight.

- Protects against moisture: The layered structure formed through co-extrusion limits water absorption, reducing swelling, warping or weakening in rainy or humid environments.

- Maintains outdoor performance: Co-extrusion combines UV-resistant and moisture-protective layers, helping profiles retain strength, alignment and surface quality even under extreme weather conditions.

Co-extruded layers ensure PVC profiles remain durable, stable, and visually consistent, making them reliable for long-term outdoor use.

Reduces Maintenance Needs

Without a doubt, a crucial benefit of co-extrusion is that it produces PVC profiles that require less frequent cleaning and upkeep. The outer layers resist dirt, stains, and chemical wear, keeping the profiles looking and performing well over time.

- Resists dirt and stains: Co-extruded surfaces prevent grime, dust, and stains from penetrating the profile, making cleaning quicker and easier.

- Handles cleaning chemicals: The protective outer layer formed through co-extrusion withstands detergents and cleaning agents without damage, preserving surface quality.

- Supports long-term performance: Co-extrusion ensures profiles maintain their shape, appearance and functionality even with minimal maintenance, reducing effort and costs for building managers and homeowners.

By using co-extrusion to produce low-maintenance PVC profiles, windows, doors, and panels stay durable, attractive, and functional for years.

Conclusion

Co-extrusion transforms PVC profiles into high-performance solutions for industrial and construction applications. By combining multiple layers, the process enhances impact resistance, thermal stability, weather and UV durability, and long-term reliability.

It also allows customisation of finishes while reducing maintenance needs, giving profiles both strength and aesthetic appeal. Each layer serves a specific purpose, from structural support to surface protection, ensuring consistent performance under daily stress and extreme conditions.

Co-extruded profiles deliver precision, durability, and versatility, making them a smart choice for windows, doors, and panels that must meet the demands of modern buildings while retaining appearance and functionality for years.

Are you looking for high-quality co-extruded PVC profiles for demanding applications? M3 Extrusion specialises in precision-engineered co-extruded PVC profiles designed to deliver strong wear resistance, reliable weather protection and long-term UV stability across a wide range of uses.

Frequently Asked Questions

How does co-extrusion affect durability?

By combining layers, co-extruded PVC profiles resist scratches, stains, and UV damage. The inner layers add strength and rigidity, reducing warping or bending over time, which makes the profiles last longer in demanding industrial and construction environments.

Can co-extruded PVC profiles handle extreme temperatures?

Yes. Co-extrusion improves thermal stability by using layers that control expansion and contraction. This keeps profiles stable in heat or cold, ensuring they maintain shape and performance under varying environmental conditions.

Are co-extruded profiles energy-efficient?

Multi-layer or multi-chamber designs created through co-extrusion improve insulation. This helps reduce heat transfer, making windows, doors, and other PVC profiles more energy-efficient in buildings and industrial applications.

Can co-extrusion improve the appearance of PVC profiles?

Yes. The outer layer can be customised with different colours, textures, or finishes, including wood-like or glossy surfaces, while maintaining the strength and durability provided by the inner layers.